Understanding Fibre to Fabric for Class 6

Fibre to Fabric

How are the clothes you wear made, have you ever thought about it? It is intriguing to turn Fibre to Fabric. It is an intricate process that transforms raw fibres into yarns, and then into woven or knits fabric. Fibres fall into natural and synthetic categories. Most industries ranging from the textile, fashion and apparel industries to home textiles, industrial application, etc. need this process to complete the cycle of moving from fibre to fabric. In this lesson you will go from fibre to fabric and learn about the different types of fibres, where they come from and how they are turned into the clothes we wear each day.

What are Fibres?

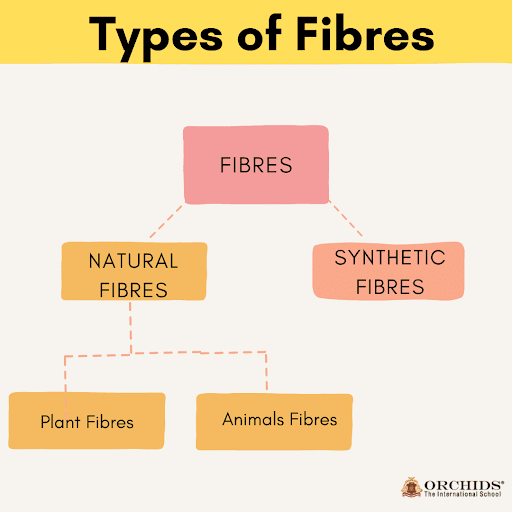

Fibres are long, slender threads that can be twisted into yarn and woven or knitted into fabric. They form the basic building blocks of textiles, and are broadly categorized into two types.

-

Natural Fibres

These fibres are also obtained from plants and animals, and are biodegradable. They are also environmentally friendly and easy to wear.

-

Plant Fibres: Cotton fibre, jute fibre, flax, fibre cloth comes from plants. Such fibres are soft, breathable and used to make clothes and household items.

-

Fibers from Animals(wool fiber, silk) -- Polymeric materials (fibers) obtained from living organisms are called natural fibers. They offer warmth and a sumptuous texture.

-

Synthetic Fibres

These are synthetic, manufactured using chemical processes, and are very strong. Some examples would be polyester, nylon, acrylic, and rayon. Synthetic fibres are notoriously resistant to wrinkles and water, making them appropriate for outdoor clothing and industrial use.

History of Clothing

Even in ancient times, simple garments made from leaves, animal skin, or woven grass were used to cover their bodies. As societies developed, people became adept at deriving fibres from plants and animals to produce the fabric. Linen (made from flax) was popular among the Egyptians; the Indians were the first to cultivate cotton. This rich fabric became a valuable commodity traded on the Silk Road of medieval times.

Fun Fact: The Indus Valley Civilization (around 2500 BCE was one of the earliest known civilizations to spin cotton into fabric!

How Are Plant Fibres Obtained?

-

Cotton

Cotton is a product of the cotton plant which is mainly found in tropical regions that has black soil. It is among the most commonly used fibres in textile manufacturing.

Process of Extraction:

-

Harvesting: Picked cotton bolls are harvested when mature.

-

Ginning: Machines separately extract fibres from seeds.

-

Spinning: Fibres are twisted into yarn.

-

Textiles: Yarn is spun into cloth for use in many ways.

-

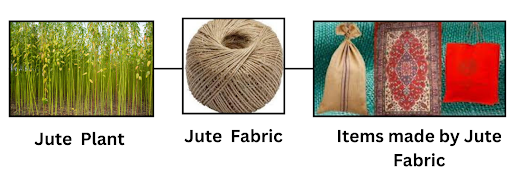

Jute

Jute is a natural textile made from the stalks of jute plants and is most widely grown in India and Bangladesh. It is a robust and rough fiber used for commercial and domestic purposes.

Process of Extraction:

-

Retting: Stems are immersed in water, to loosen fibres.

-

Stripping: Fibres are detached from stalks.

-

Spinning & Weaving—dehydrated fibres transformed into yarns then woven into fabric for sacks, ropes, and mats.

Real-Life Example: Natural jute fibre is used to make shopping bags and ropes.

How do We Get Animal Fibres?

-

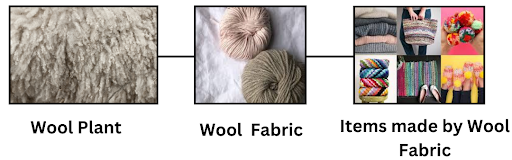

Wool

Wool from sheep, goats, + camels, + rabbits. Although not as prevalent as cotton or wool, there are many people who use it for fabricates warm clothes and blankets.

Process of Wool Production:

-

Shearing: Removing the fleece (coat) from the animal.

-

Scouring: Scraping off dirt and grease.

-

First sorting: Fibres are sorted according to their quality and length.

-

Spinning: Wool fibers are spun into yarns and woven or knitted into fabric.

-

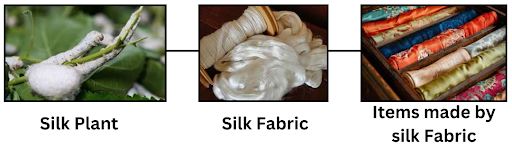

Silk

Silk comes from silkworms. The process — called sericulture — must be undertaken with extreme care.

Process of Silk Production:

-

Cocoon: The silkworm creates cocoons out of silk fibres.

-

silkworm cocoons are boiled to retrieve silk fibers

-

Their strands are spun into silk yarns and woven into fabrics, resulting in smooth, silky textiles.

Fun Fact: Silk was discovered in China 2700 BCE and kept a secret for centuries! Ironically silk became one of the most valuable trading commodity for centuries.

Synthetic Fibres

Natural fibres v/s synthetic fibres: Synthetic fibres are fabricated from chemicals (unlike natural fibres) and are produced in vast amounts. They are:

-

Stronger and harder than natural fibres.

-

They are wrinkle resistant and easy to care.

-

Hydrophobic, great for rain jackets and activewear.

Fiber-Carbon (cloth, carbon fiber, fabric, fibrous cloth, cloth, rayon, polyester, nylon, acrylic, fiber-optic fabric): These fibres are found in industrially engineered applications from car interiors to medical textiles and outdoor wear.

Did You Know? Nylon was the first completely synthetic fibre when it was discovered in 1935, but its strength and versatility changed the textile industry forever.

Different Fibres With Their Properties:

Properties of Cotton Fibre

-

Soft and highly breathable, ideal for summery wear.

-

It absorbs water well, making it suitable for humid weather.

-

Friendly biodegradable and minimizes environmental pollution.

-

Tends to wrinkle easily and needs to be ironed for a crisp look.

Uses of Cotton

-

It is making it clothes. bedsheets and towels.

-

Making medical bandages and gauze.

-

Col quipueden utilizarse en denim, camisetas y telas industriales.

Properties of Jute

-

The paper is long-lasting and resistant, which makes itperfect for packaging materials.

-

Eco-friendly, reduces pollution and biodegradable.

-

The most water-absorbent, so ideal for sacks and ropes.

Uses of Jute Fibre

-

Sacks, ropes, carpets and mats.

-

To develop sustainable packaging materials.

-

Making handicrafts, wall hangings, and rugs.

Properties of Wool

-

Insulation (Wherever you go, wear the thickest things)Very warm and create Atmosphere, will lock yourself in this word.

-

Resilient and strong, so clothing holds its shape.

-

Pulls moisture, but the moisture does not feel wet, so it is comfortable in winter.

Uses of Wool

-

Knitting winter clothes like sweaters, scarves, and gloves.

-

Commonly used for carpets, upholstery and home furnishing

-

Producing distant coverings and warmness fabrics for cool climates.

Fun Facts:

-

Flax-dated fabric, the world’s oldest woven textile, preceded that by at least 9,000 years.

-

The fiber from sheep has lanolin in it, which provides NATURALLY water repellant warmth.

-

And did you know that one cocoon of silkworm can yield approximately 900 meters of silk thread!

-

Carbon fiber fabrics are used in aerospace due to their high strength to weight ratio.

Things you have learned!

- Learned that fibres are of two main types: natural (like cotton, jute, wool) and synthetic (like nylon, polyester).

- Found out how fibres are taken from plants and animals using steps like ginning, retting, shearing, and sericulture.

- Understood how fibres are made into yarn, and then turned into cloth by weaving or knitting.

- Discovered the special features of different fibres—cotton is soft, jute is strong, and wool keeps us warm.

- Explored man-made fibres like carbon fibre and how they are used in modern things like cars and clothes.

- Realized the difference between eco-friendly (good for nature) and non-eco-friendly materials.